1846

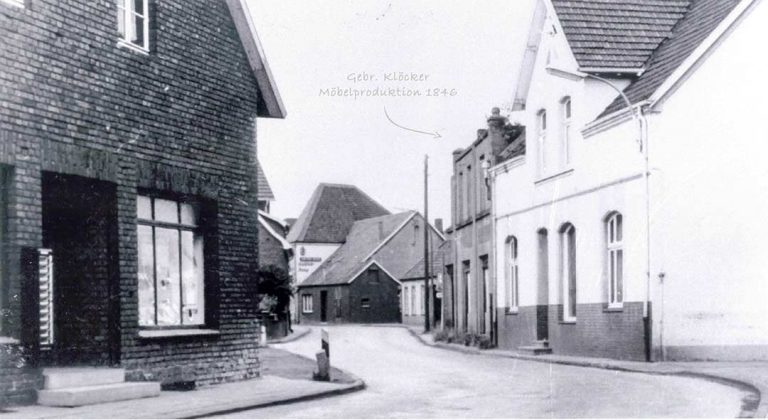

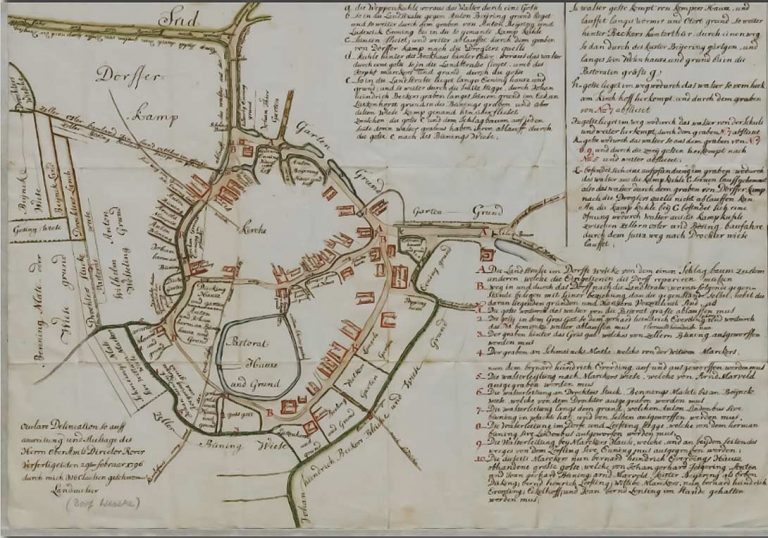

The history of Klöcker Bros. goes back to almost 300 years. First official records of the company from Borken date back to the year 1846. All documents subject to the older history of Klöcker unfortunately have been destroyed in two serious fires.

Read more

Klöcker Bros. always have sustained their position in the market without any subventions, initially with the production of high-quality furniture at the original site opposite the church in the centre of Borken-Weseke.

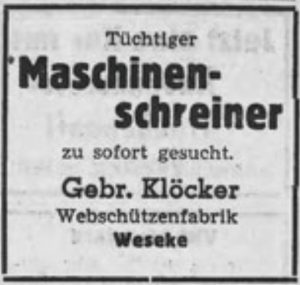

The industrial revolution especially benefits the expansion of the textile sector in the Münsterland region in Western Germany. For this reason, accessories on wooden basis for mechanical weaving looms are being included in the production program in the course of time.

Within the scope of this development, Klöcker Bros. focus on the production of weaving shuttles in the textile division and become known worldwide as one of the leading quality suppliers for automatic weaving shuttles during that time.

1900

As a German manufacturer of shuttles, Klöcker starts to produce metallic spare parts for textile industry by the beginning of the 20th century, particularly since alternative raw materials increasingly replace wood throughout the general machine building.

read more

In view of the increasing demand for more durable materials in mechanical engineering, which are gradually replacing wood as a raw material, the company responded flexibly to the new requirements of the industry.

Furniture production continued alongside the

new manufacturing areas.

1945

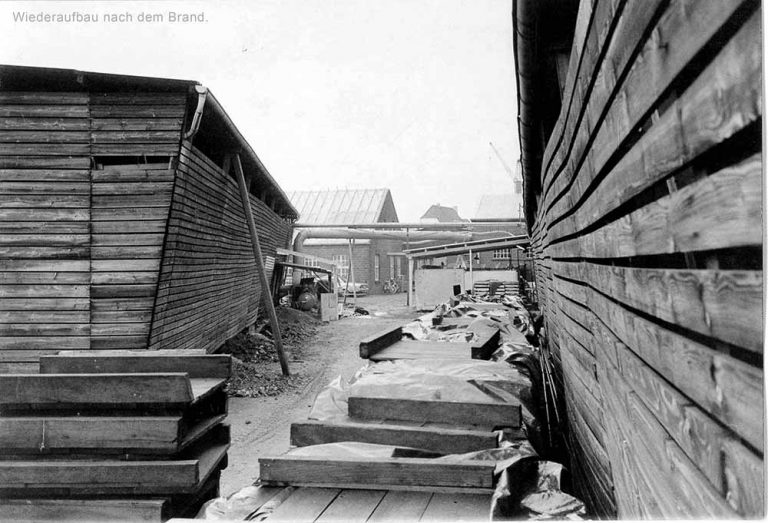

Directly after the second world war, the original site at Flopsplatz in the centre falls victim to a fire.

read more

Insurance assets – paid out in Reichsmark in record time – are practically worthless due to the upcoming

monetary reform.

However, the reconstruction of the company is effected by the unprecedented personal commitment of the owners of that time, Messrs. Heinz and Franz Klöcker.

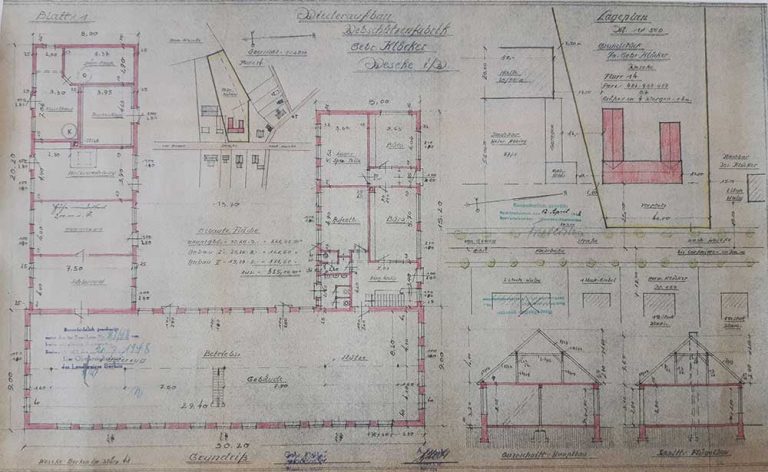

1948

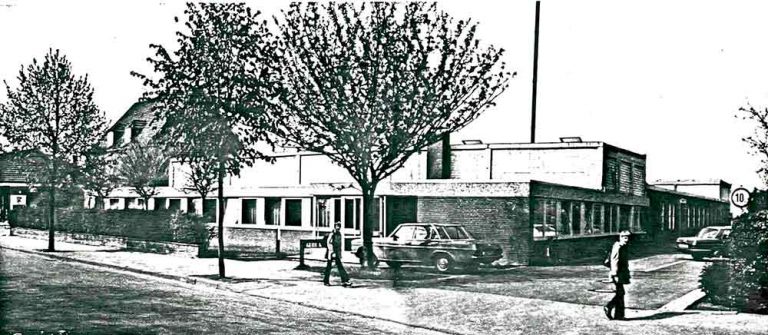

Consequently, a new start is being made at today’s site at Hauptstrasse in the year 1948:

read more

The furniture sector is being given up in favour of an intensification of production of accessories for textile machinery. Klöcker Bros. construct a new building at today’s premises. A new department for mechanical accessories

is being established.

1960-70

In the 1960s and 1970s, the loom was further developed by replacing conventional spindle shuttles with significantly faster, automatic shuttles.

read more

These continue to be made from pressed wood and form the main product in the production range.

Klöcker has always focused on the highest quality, and deliberately distanced itself from the mass production of inferior plastic spindle looms, in order to offer its customers durable and precise products.

1974

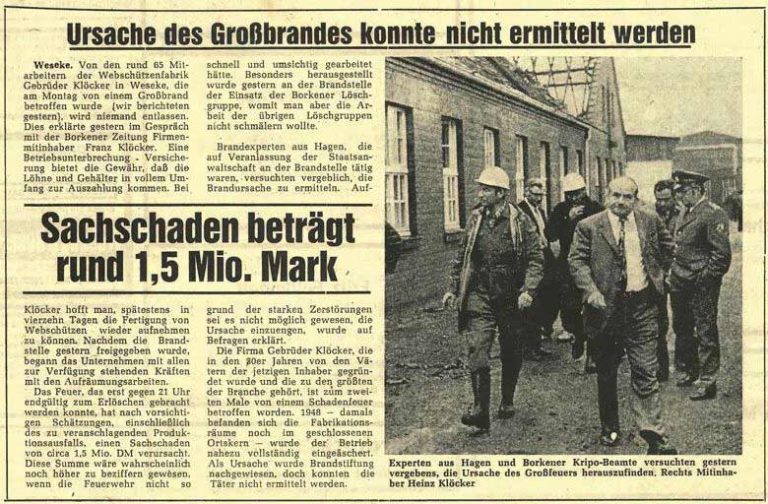

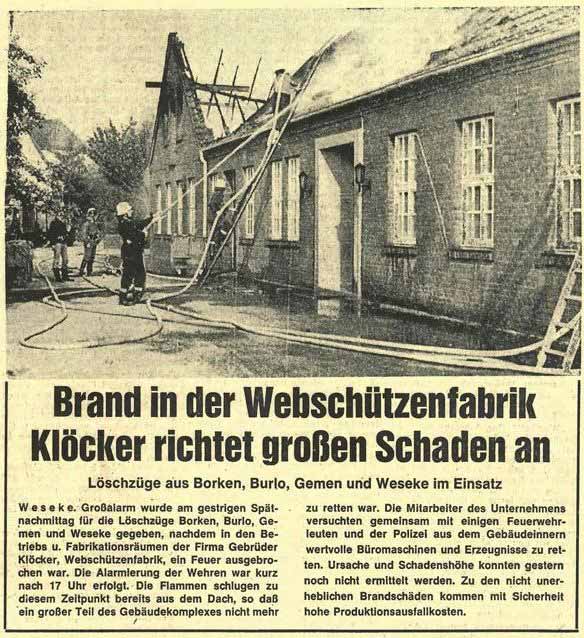

In 1974, a serious fire destroys the company Klöcker at its new site at Hauptstrasse again.

read more

There are rumors about malicious arson. The building is being reestablished. Two other halls follow

during the next years.

In the following years, two more halls were built to expand production and meet the growing demand.

1978

At the end of the 1970s, the textile industry in the Münsterland region underwent dramatic changes. Cheap products began to compete with the domestic economy, and new, automated weaving machines entered

the market.

read more

The market is being conquered by the automated weaving machines transporting the filling yarn by so called projectiles, rapiers or by air or water power at considerably higher speeds than weaving shuttles may reach.

Today, these machines can reach speeds of up to 1,200 shots per minute, and at trade fairs, speeds of up to 2,000 shots per minute are even demonstrated.

1990

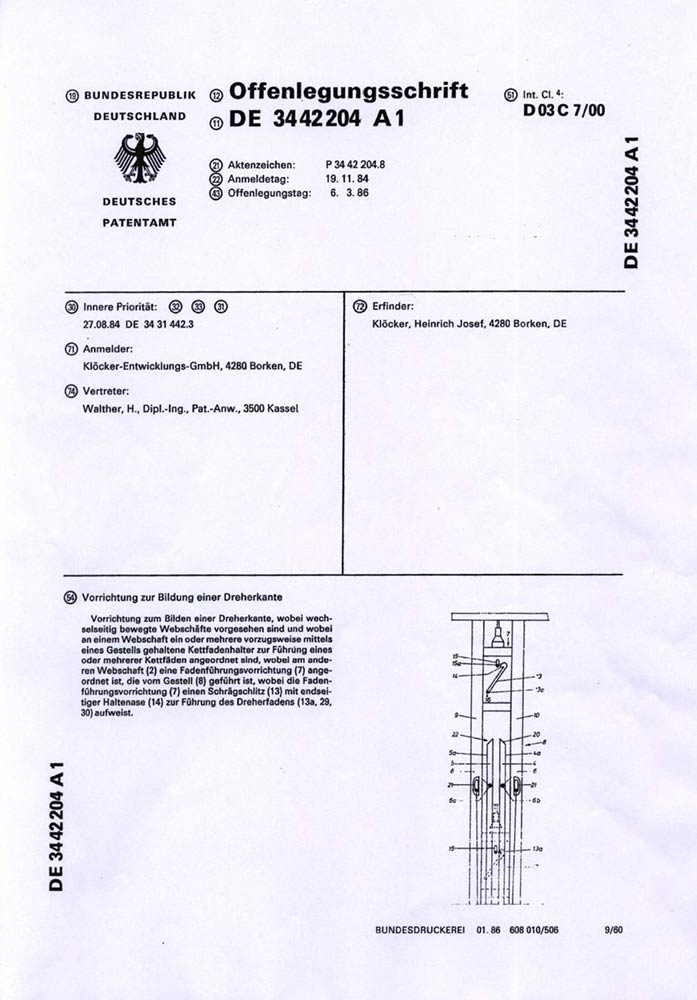

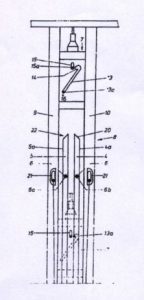

Within the scope of a change in leadership in 1990, the owners of that time, Messrs. Heinz and Franz Klöcker, surrender the responsibility for the company without any reservation to their successors and today’s managing partners Matthias Klöcker and Dr. Christoph Schwemmlein who expand the development department in Borken successively.

Read More

Under their leadership, the development department at the Borken site is continuously expanding. The mechanical versions are continuously optimized with improved materials, including carbon fiber composites.

Later, mechatronic components adapted to modern weaving machines are integrated, with CAN Bus connectivity playing an important role.

Among other things, Klöcker supervised the first graduate student in the early 1990s, and from then on focused on close cooperation with universities in Germany and abroad. The scientific supervision of diploma theses, and later bachelor’s and master’s theses, is continued on a regular basis.

1995

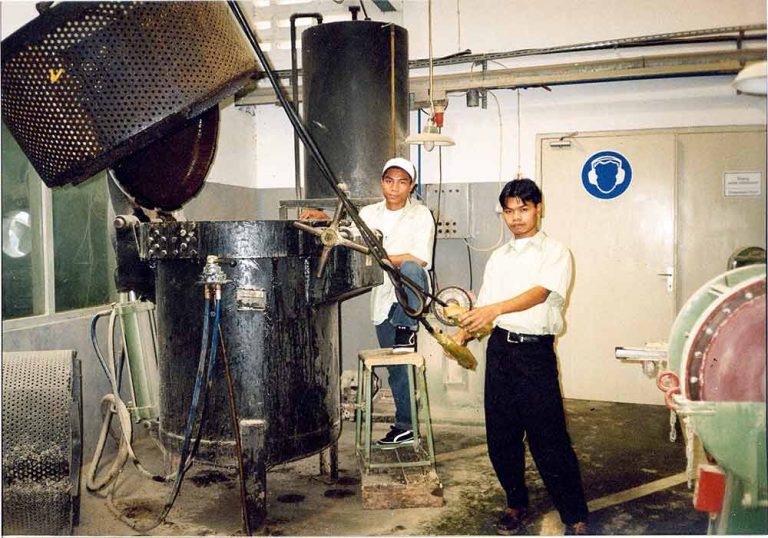

In the mid-1990s, the production of weaving shuttles was relocated to a new site in Bandung, Rancaekek, Indonesia. However, the selection, cutting, drying, and pressing of Croatian white beech wood for the weaving shuttles remains in Borken, where the necessary expertise is available.

read more

The new SKD plant successfully weathered the subsequent Asian crisis, as shuttle looms were still widely used there, and the company was in a strong financial position.

Thanks to state-of-the-art production methods, PT. SKD developed into a strong manufacturer of mechanical textile machinery accessories under German management.

High-quality products were manufactured at the Bandung site in Indonesia, covering an area of around 6,000 m² in two large halls and adjoining buildings.

2000

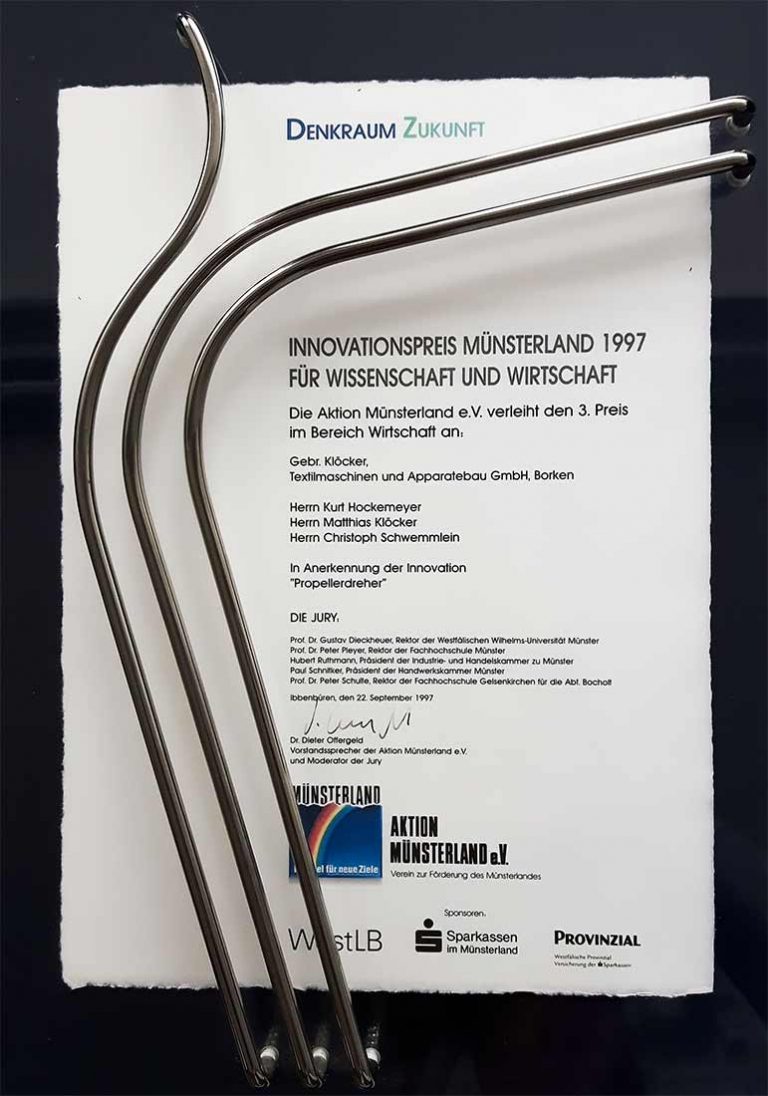

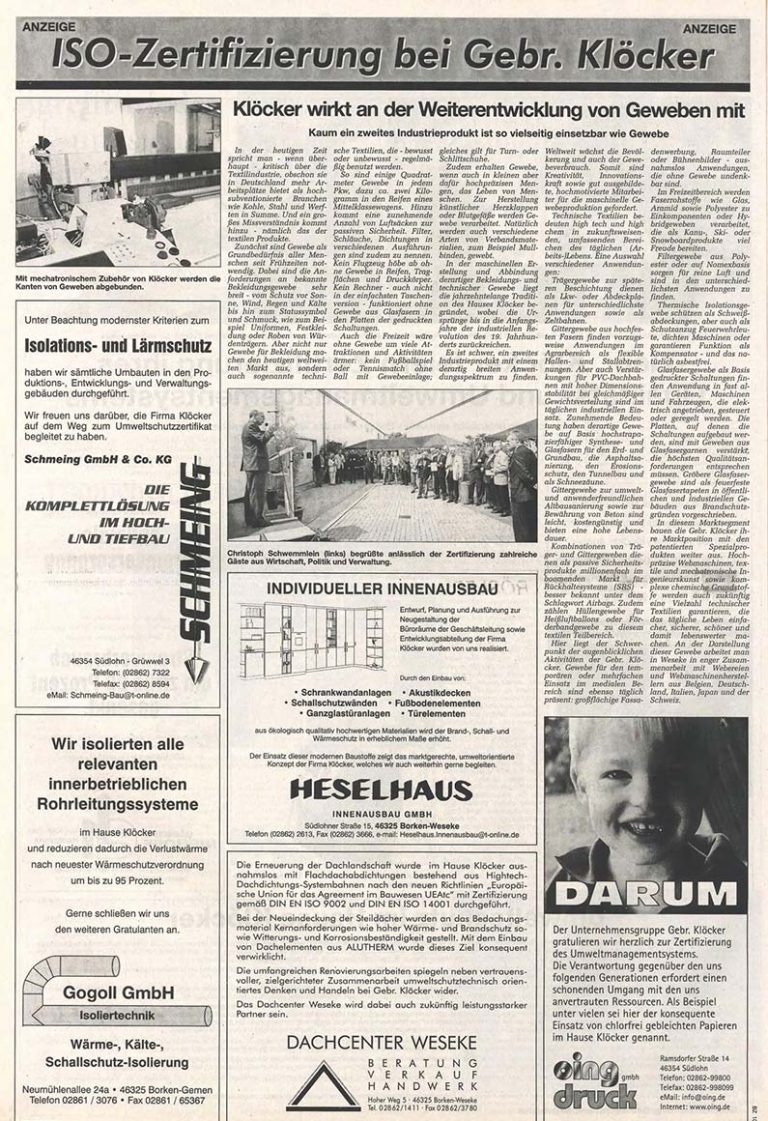

At the turn of the millennium, Klöcker implements a quality and environmental system according to DIN EN ISO 9001 and DIN EN ISO 14001 respectively after having passed the extensive examination through the Technical Inspection Authorities in charge, while the Indonesian site follows the relevant guidelines as well.

Numerous guests from economy, politics and administration participate in celebrating the certification.

Read more

For many decades, tools have only been constructed for internal purposes at Klöcker. The experiences having been developed to a profound know-how in this range are being used by the company for contract manufacturing by beginning of the new millennium, while expanding business activities by the field tool manufacture and construction.

The new division in Borken is being completed by comprehensive investments in machinery, high-qualified staff as well as reliable C-technologies. After three wars and two inflations, Klöcker Bros. are optimistic to sustain their success story by making an advance in tool manufacture.

2012

In 2012, the production of weaving shuttles is being shut down in favour of focussing on tool engineering and moulding technology according to plan, thus considering the trends in view of the structural development in the textile markets which may be observed in the long run. Decisive factors are the long-term basis with the acquisition of the raw material on the one hand as well as globally rising energy costs on the other.

2013

SKD sells the machinery being adapted to the production of weaving shuttles and moves into the new location at Bandung Biz-Park in order to adequately attend the extended production program. The production of industrial parts for the automotive and air conditioning sector is being focussed from now on.

read more

At the same time, the released area at the site in Borken is being used to build up an assembly line for the newly developed K-GLASS® Selvedge Motion product range, going along with the fabrication of all necessary injection moulds and special tools for manufacturing the needles and effecting the superfine polishing.

The K-GLASS® Selvedge Motion satisfies as unique feature the special demands of finest electric glass being used for the production of all current circuit boards and thus marks another step stone in the history of Klöcker Bros.

2022

read more

Apart from a newly implemented clean-room environment, injection moulding machines for ceramics as well as debinding and sintering furnaces find their way into the company. At the same time, sustainability is a major issue being met by features such as fully electronic control and software-based optimization of consumption. Adding to individual medical products made of special synthetic material, dental and surgery ceramics are now standard being produced “Made in Germany”.

Klöcker today

The name and the brand Klöcker stand for first-class quality as well as reliability. The development program is exclusively adapted to the market by emphasizing the benefit of the customer on one hand and covering the prospective needs with innovations on the other hand.

Instead of outsourcing, Klöcker consistently focuses on a high level of vertical integration in order to ensure quality and preserve intellectual property. Key components are predominantly manufactured in-house, which creates independence from suppliers. This philosophy is supported by experienced specialists who have shaped the company for decades and continuously develop its expertise.