Klöcker in medical technology

For 25 years, we have been passionately committed to innovative solutions in medical technology.

What started with woven gauze bandages has become an outsourced division with state-of-the-art technology and controlled manufacturing processes. We produce products that support the manufacturing of technical fabrics, such as textile implants, as well as high-precision packaging solutions for dental medicine. Our goal is to produce medical devices “Made in Westmünsterland” that guarantee the highest quality, purity, and safety.

Production facility

production

Klöcker is committed to the highest hygiene standards and close partnerships in the field of medical technology.

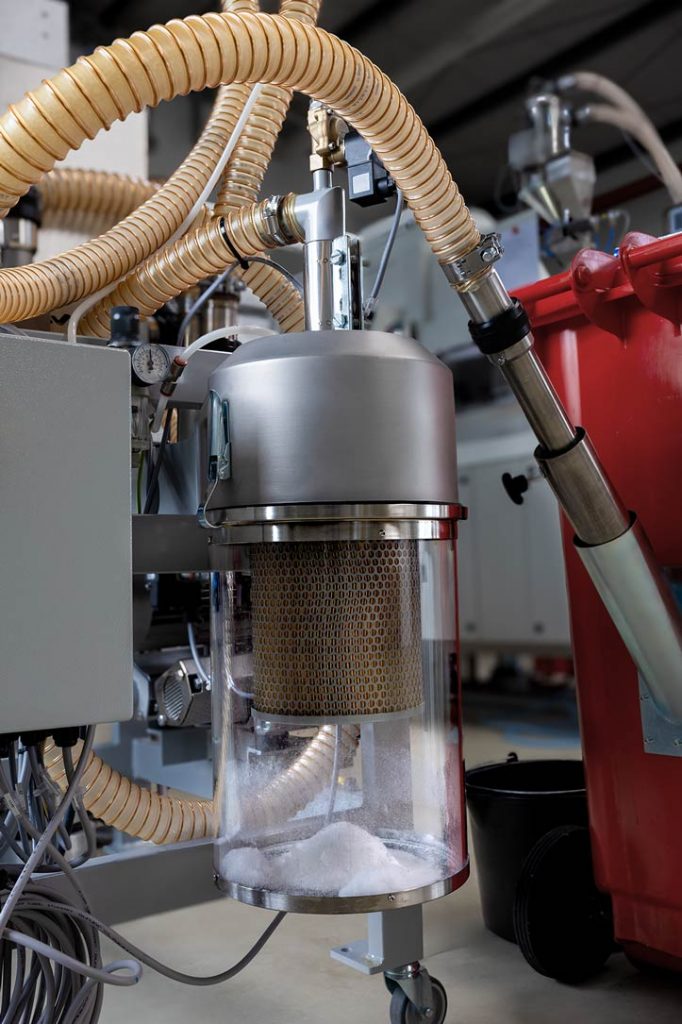

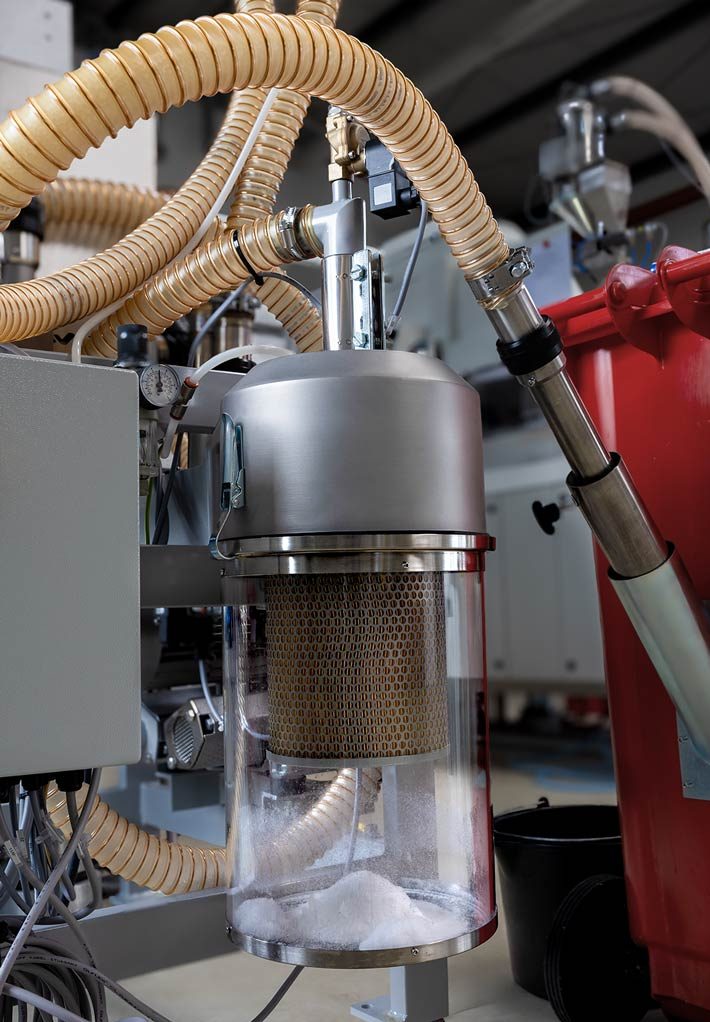

In collaboration with Absolute Medical Germany (AMG), a DIN EN ISO 13485-certified company, we have developed a secure production process for medical technology. Our partner company specializes in cleanroom solutions and medical technology training, supporting us with its expertise.

AMG has built and equipped two clean rooms at Klöcker that comply with ISO standards and are directly connected to our validated machines. This ensures that products are processed seamlessly and without external contact.

At the same time, trained staff ensure airtight and hygienic packaging.

Close cooperation and short delivery routes allow the strengths of both companies to be combined optimally.

This results in a consistently hygienic production process with a high degree of vertical integration.

Focus & Expertise

With our weaving technology, we are taking our first steps toward medical technology.

Until today, our products have been used to manufacture elastic fabrics for demanding applications such as arteries, eardrums, and heart valves, where sterility, elasticity, and durability play a decisive role in their manufacture. Building on this experience, we have further developed our portfolio:

In the latest field, dental medicine, innovative plastic products are created using modern injection molding technology. Manufactured in certified clean rooms by AMG (Absolute Medical Germany), the products are inspected by specially trained personnel.

Production facility

Our medical technology production is spread across several halls at our main location in Germany.

For the coming years, we are planning additional buildings with more machines, new manufacturing technologies,

and an expanded product range.

Medical technology

MADE IN

Westmünsterland

Manufactured to the highest quality standards.

Medical technology

MADE IN

Westmünsterland

Hygienically clean and technically precise.

Manufactured to the highest quality standards.

Klöcker in medical technology

For 25 years, we have been passionately committed to

innovative solutions in medical technology.

What started with woven gauze bandages has become an outsourced division with state-of-the-art technology and controlled manufacturing processes. We produce products that support the manufacturing of technical fabrics, such as textile implants, as well as high-precision packaging solutions for dental medicine. Our goal is to produce medical devices

“Made in Westmünsterland” that guarantee the highest

quality, purity, and safety.

For 25 years, we have been passionately committed to innovative solutions in medical technology.

What started with woven gauze bandages has become an outsourced division with state-of-the-art technology and controlled manufacturing processes.

Read more

We produce products that support the manufacturing of technical fabrics, such as textile implants, as well as high-precision packaging solutions for dental medicine.

Our goal is to produce medical devices

“Made in Westmünsterland” that guarantee the highest quality, purity, and safety.

Production facility

Partner & Production

In the field of medical technology, Klöcker focuses on the highest hygiene standards and close partnerships. Together with Absolute Medical Germany (AMG), we have developed a safe and professional production process. Our partner company specializes in cleanroom solutions and training in the field of medical technology. Certified according to DIN EN ISO 13485,

they support us with their expertise.

AMG has built and equipped two clean rooms at Klöcker that connect seamlessly with our validated machines. Products are manufactured directly in the clean room environment by the machine without any external influences. In addition, our specialists, trained by AMG, ensure airtight and hygienic packaging.

Focus & Expertise

With our weaving technology, we took our first steps toward medical technology. To this day, our products are used to manufacture elastic fabrics for demanding applications such as arteries, eardrums, and heart valves. Sterility, elasticity, and durability play a decisive role in their manufacture. Building on this experience, we have further developed our portfolio.

In the newest field, dental medicine, innovative plastic products are created using modern injection molding technology. Manufacturing and packaging take place in our halls in

specially built and certified clean rooms from AMG.

Production Facility

Our medical technology production is spread across several halls at our main location in Germany.

For the coming years, we are planning more buildings with additional machines, new manufacturing technologies, and an expanded product range.