Precision meets innovation

With state-of-the-art technology and a versatile range of machinery, we lay the foundation for the highest quality and efficient manufacturing processes. Each machine stands for precision, reliability, and progress

and is customized to the individual requirements of our clients.

BOY injection

molding machine

Clamping force: max. 50 – 60 tonnes

Injection pressure: avg. 2,000 bar

Manufacture of small plastic parts

- Efficient, accurate production

- Space-saving design

Engel injection

molding machine

Clamping force: max. 50 – 80 tonnes

Injection pressure: avg. 2,000 bar

- High repeatability

- Energy-efficient, automated operation

- Series production of plastic and ceramic

molded parts

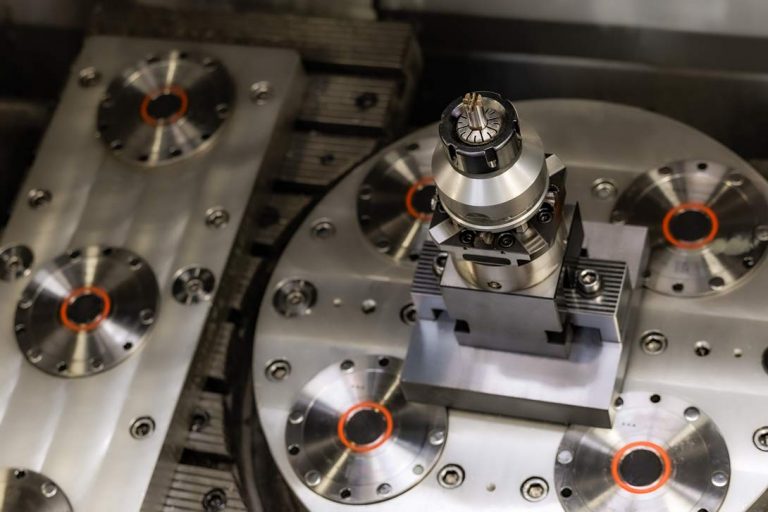

Flexible pallet changing

increases productivity- Fine cuts and complex contours

Automated, high-precision axis control

Hermle C40 Processing

center with 5 axes

Processing with 3 axes

Traverse paths: 850 mm, 605 mm, 500mm

Weight of workpiece: up to 1.700 kgs

Processing with 4 sides

Traverse paths: 700 mm, 500 mm, 500 mm

Weight of workpiece: up to 600 kgs

Simultaneous processing with 5 axes

Traverse paths: 450 mm, 450 mm, 500 mm

Weight of workpiece: up to 600 kgs

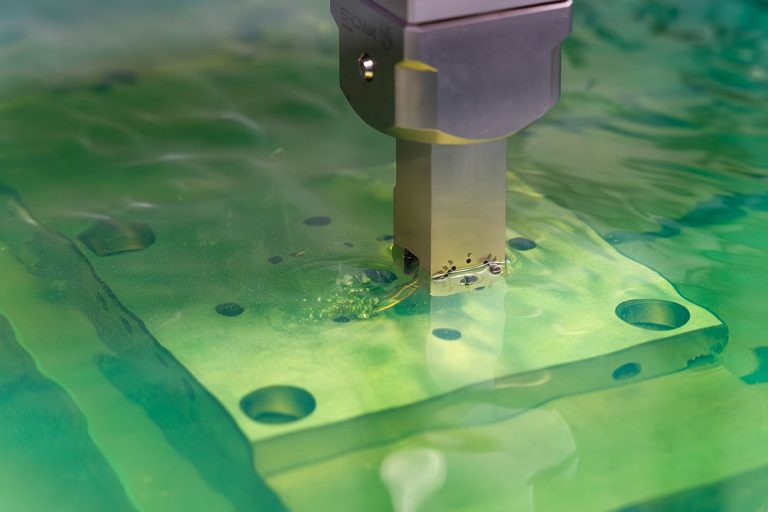

Exeron EDM 313 Vertical eroding machine

Traverse paths: 620 mm, 420 mm, 400 mm

Weight of workpiece: up to 1.500 kgs

Precise erosion of complex contours

Processing of conductive materials

Automated electrode control

Blohm Surface

grinding machine

Traverse paths: 800 mm, 400 mm, 465 mm

Weight of workpiece: up to 750 kgs

- High-precision surface grinding

- Automatic longitudinal and cross feed

Workpiece clamping via magnetic

clamping chuck

Robofil 440

Wire eroding machine

Traverse paths: 550 mm, 350 mm, 400 mm

Weight of workpiece: up to 1.500 kgs

- Precision wire erosion for

conductive workpieces - Fine surface finish up to Ra 0.2 µm

- Automatic wire feed and rethreading